| CABIN TECHNICAL SPECIFICATIONS | |

|---|---|

| EARTHQUAKE CONDITIONS | 1st Degree |

| CLIMATE CONDITIONS | Suitable for 3rd climate zone |

| SNOW LOAD | 80 Kg/m² |

| WIND SPEED | 80 Km/Hour (Cabin must be fixed to the ground) |

| METAL PARTS | ST 37 Galvanized metal |

| CEMENT BORAD | TS EN 634-2 Cement Board - Fire reaction class “B” |

| ISOLATION | TS EN 13165 - Polyurethane foam-Fire reaction class “B” |

| CHASSIS LOAD CAPACITY | 200 Kg/m² |

| BASE | |

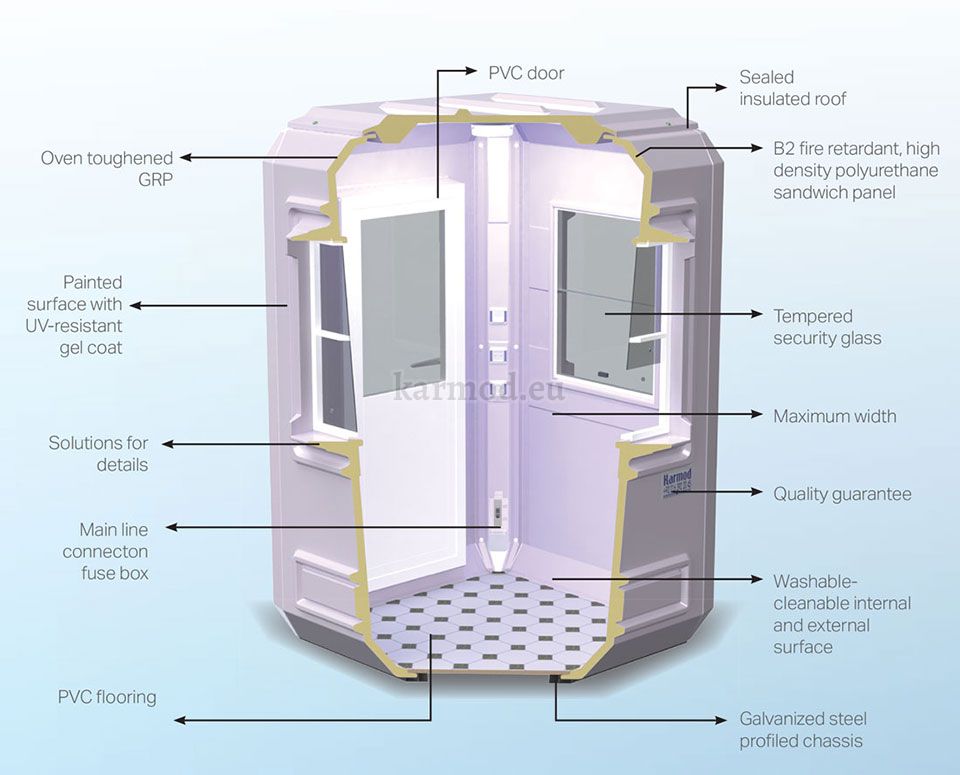

| SYSTEM | Being applied on specially shaped steel construction and single supporting galvanizeed profile parts. The area, where the cabin will be located must be flat. |

| FLOOR COATING | PVC Mineflo with 2.5 mm thickness is used as floor covering on boards of odorless and fireproof Cement board with 16 mm thickness as base covering of the Cabin. |

| OUTER WALL | |

| MOLD SYSTEM | Special shaped steel construction and aluminum molds. Cabin is made out of Polyester sandwich panel by being pressed inside the molds through an automated production technology that is one of its kind. the solvent gas is removed from gelcoat sandwich panel at 50’C. |

| CABIN MANUFACTURING SYSTEM | Being manufactured from fiber glass reinforced polyester material as double-walled polyurethane sandwich panel that is treated inside oven at 50 degrees. After screwing the specially shaped modular panels together, anti bacterial neutral silicone is added, which protects the cabin agains water, snow, dust, insects and bacteria. In addition to that it gives the cabin hygienic and long-lasting structure. |

| OUTER SURFACE COATING | Ultraviolet radiation resistant, polyester-based, off-white colour, isophthalic acrylic based special gelcoat is used, which gives the cabin washable, anticorrosive, and rustproof features. |

| INNER SURFACE COATING | Ultraviolet radiation resistant, polyester-based, off-white colour, isophthalic acrylic based special gelcoat is used, which gives the cabin washable, anticorrosive, and rustproof features. |

| WALL INSULATION | 40 density 35 mm thickness, polyurethane foam is injected by using 140 bar Italian made machine. |

| INNER WALL | |

| SYSTEM | Produced as special shaped panels that are made out of GRP Glass fiber reinforced polyester and injected rigid polyurethane foam. |

| INNER SURFACE COATING | The composite panels are formed from Isophtalic acrylic special bright off white (fluorescent) colour with gelcoat and fiberglass reinforced polyester. |

| WALL INSULATION | 42 density new generation gaseous rigid polyurethane foam is injected with 35 mm thickness by using high pressure machine inside the panels, which provides high head and sound insulation. |

| GENERAL OUTER WALL SPECIFICATIONS | |

| Outer and inner surfaces of the panels of Karmod cabins are manufactured from off-white colored gelcoat material that is resistant for temperatuve between +60 degrees and -50 degrees. Outer and inner panels are resistant to weather conditions and have anti-corrosive properties. The cabin panels are washable, stainless , rotproof, and easy to clean. | |

| ROOF | |

| ROOF SYSTEM | Being manufactured from fiber glass reinforced polyester material as double-walled polyurethane sandwich panel. After screwing the specially shaped modular roof panels together with sealed bolts, anti bacterial neutral silicone is added, which protects the cabin agains water, snow, dust, insects and bacteria. In addition to that it gives the cabin hygienic and long-lasting structure. |

| ROOF INSULATION | 42 density Polyurethane foam is injected. |

| INNER SURFACE COATING | Ultraviolet radiation resistant, polyester-based, off-white colour, isophthalic acrylic based special gelcoat is used, which gives the cabin washable, anticorrosive, and rustproof features. |

| OUTER SURFACE COATING | Ultraviolet radiation resistant, polyester-based, off-white colour, isophthalic acrylic based special gelcoat is used, which gives the cabin washable, anticorrosive, and rustproof features. |

| DOORS | |

| OUTER DOOR | White colored PVC door with espagnolette lock. Dimensions are 71,5*184,5cm and 4 mm thickness door glass is used. Unless requested by the customer , doors are produced in white color. |

| WINDOWS | |

| WINDOW | Composed of powder coated white color aluminum frame. Unless requested by the customer , frames are produced in white color. |

| GLASS | 4 mm thickness tempered glass is used. This is in order to save the people in the cabin in case of any damage of the window. |

| PAINTS | |

| METAL PARTS | From size 150 * 150 up to 270 * 270 size 1.5 mm thick galvanized steel profiles are used for chassis. For cabins above 270*270 size the chassis are made from profiles, and one coat of Rapid prime paint is applied. |

| "ELECTRIC INSTALLATION (Gathered on inside corner covering) | |

| CABLE | 3x2.5 NYM Cable for 2000 W 220 Volt electric power, and 2x1.5 TSE (Turkish Standards Institute) certified, first class brands cable for lighting are used. |

| FUSES | TSE certified, first class brands 16 Ampere fuses are used. |

| LIGHTING FITTINGS | TSE certified, first class brands are used. |

| SOCKETS AND SWITCHES | TSE certified, first class brands are used. |

| SANITARY SYSTEM(surface mounted) | |

| SANITARY WARE | TSE certified, first class brands are used. |

| CLEAN WATER PIPE | TSE certified, first class brands are used. |

| WASTE WATER PIPE | TSE certified, first class brands are used. |

| OPTIONEL ACCESSORIES | |

| Countertops, tables, shelves, sinks, blinds, ventilation fans, internal partitions and WC are optional accessories that can be added upon request. | |

| SHIPMENT | |

| In cases when it is impossible to lıft with crane, there are specıal chassis which allow transportation with forklift or transpallet. The vehicle must approach as far as the area where the cabin will be downloaded. | |

Karmod Prefabricated Building Technologies has the right to make modifications in the Technical Specifications.